Our Products

Next Generation

Hollow motor shaft

|

|

|

|

USUI’s hollow motor shaft is a shaft that aims to reduce weight and improve cooling performance by making the inside of shaft hollow.

By combining the hollow pipe material and forged material using friction welding, it is possible to support various sizes and reduce weight while maintaining the required strength of the shaft.

We will propose the optimum motor shaft for electric vehicles that require weight reduction to increase efficiency.

Amorphous Alloy Technology

Amorphous Alloy TechnologyAmorphous alloy features high corrosion resistance, high wear resistance and high magnetostrictive performance. USUI's new technology is a unique thermal spray with an ultra-rapid cooling method that works well with thin metal plate and row metal material. FeatureCorrosion resistance● High corrosion resistance due to the formation of a highly corrosion-resistant film on the surface. Magnetic properties● Because the atoms are randomly arranged, it has no magnetic direction and has excellent magnetic properties. Abrasion resistance● It has no crystals and high hardness, so it has excellent wear resistance. Magnetostrictive● When deformed, the magnetic properties change with high sensitivity, making it possible to detect strain without contact. Manufacturing TechnologyIt is possible to produce thin plates of 300 μm or more, which cannot be achieved with conventional manufacturing methods. (Conventional method: 50 μm foil) Application Examples

・Torque sensor (high magnetostrictive)

|

High-pressure hydrogen piping for fuel cells (FCVs)

High-Pressure Hydrogen Tubes for Fuel CellThis is a stainless tube which is used to deliver high pressure hydrogen gas from a tank.

FeatureImproved assembly workabilityThe connection part has a metal seal structure with nut fastening, which improves assembly workability. Extremely high level of cleanliness● The inside of the pipe has achieved an extremely high level of cleanliness so as not to affect the system. High airtightness● Provides high airtightness due to the stainless steel seamless pipe and integrally molded tube end seal. |

Automotive Tubing

Tube Material

Nylon Tube

Nylon tube is suitable for various applications from commercial vehicles to passenger cars, and for fuel, air brake, cooling, etc.

Surface Treatment

On automotive parts, usually rust preventive surface treatment is applied. Zinc based plating or nickel based plating is often used since they have very reliable performance among various treatment methods.

Single Walled Steel Tubing (Hycolin™)

Hycolin™ is an electric resistance welded steel tube specially made, which is manufactured from electrolytic metal-coated steel strip (one surface). The strip is wound into tubular and then welded together on both edges to form continuous strip. This tube possesses higher withstanding pressure and excellent mechanical properties. And further more, is also equipped with the superior reliability on bending process and end terminal forming process. The tube is applied for several purposes such as fuel pipes and oil pipes on vehicles, tubes for heat exchanger, and pipes for hydraulic piping. Double Walled Steel Tubing

Double Walled Steel Tubing is a steel tube for pressure piping, which is manufactured from electrolytic copper coated steel strip (both surfaces). The strip is wound into continuous tubular with double-layered wall and then copper brazed in a special furnace using the coated copper as filler metal.

Double Walled Steel tube possesses both higher pressure fatigue strength and higher vibration fatigue strength higher withstanding pressure and higher vibration fatigue strength.

|

Fuel Piping Related Products

Bundled tube

Bundled tube is a set of fuel lines which are installed under the floor and in the engine compartment of a vehicle as fuel tubes and brake tubes etc. By manufacturing each pipe in-house, we are able to achieve low cost. We can meet customers' requirements with our self-developed facilities to process various types of end forming, bending, and assembly.

|

Powertrain

Cooling Related Parts

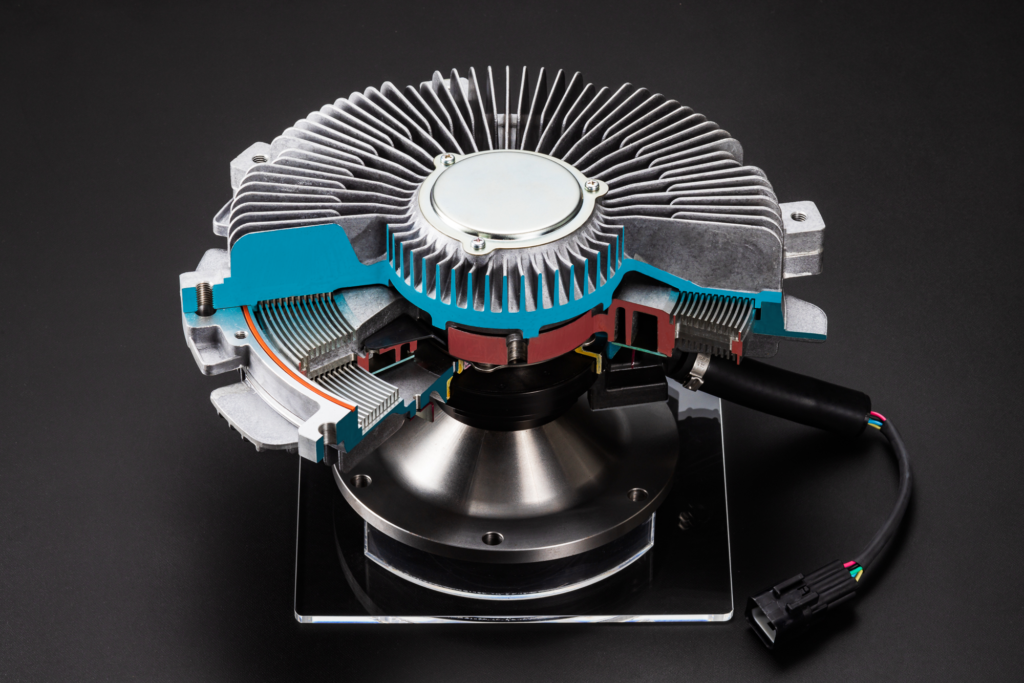

Externally Controlled Fan Drives (ECFD™)

ECFD™ is a fan drive with the rotation speed controlled via electrical signal externally fed to solenoid valve, while conventional Fan clutch is self-controlled using bi-metal sensing air temperature passing through the radiator. Several related data, such as temperature of engine cooling fluid, engine rotation speed, and cooling fan rotation speed are fed into ECU. ECU calculates desirable fan speed at each moment and transmits it as control signal to ECFD™ in electrical signal form so as to maintain fan rotation speed in desired condition.

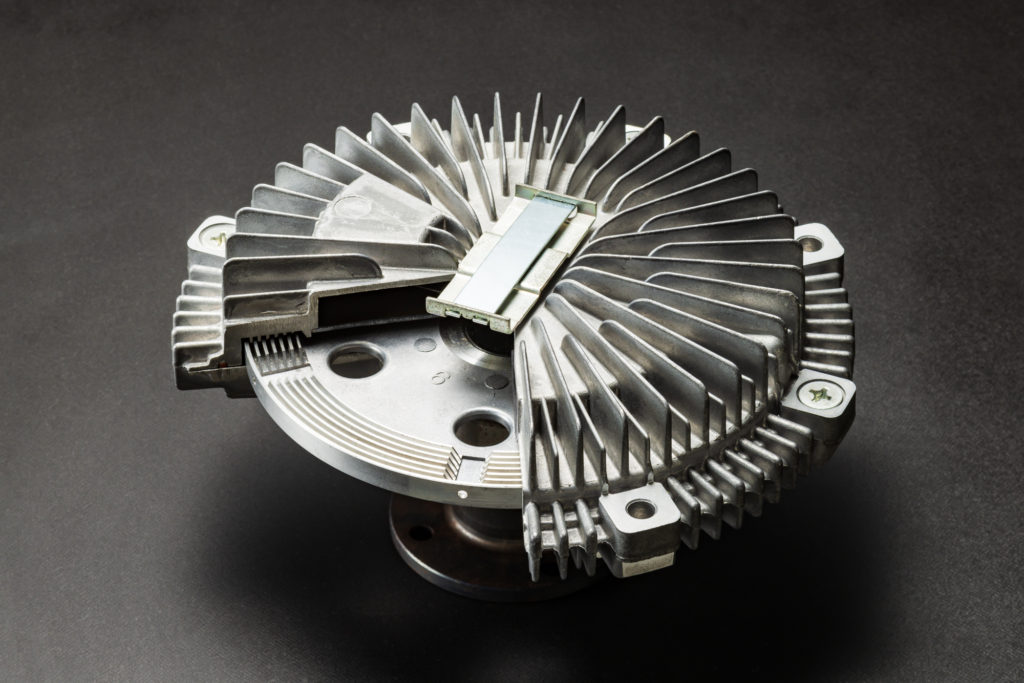

Fan Clutch

Fan clutch is a fluid clutch to adequately control rotation frequency of the fan for engine cooling.

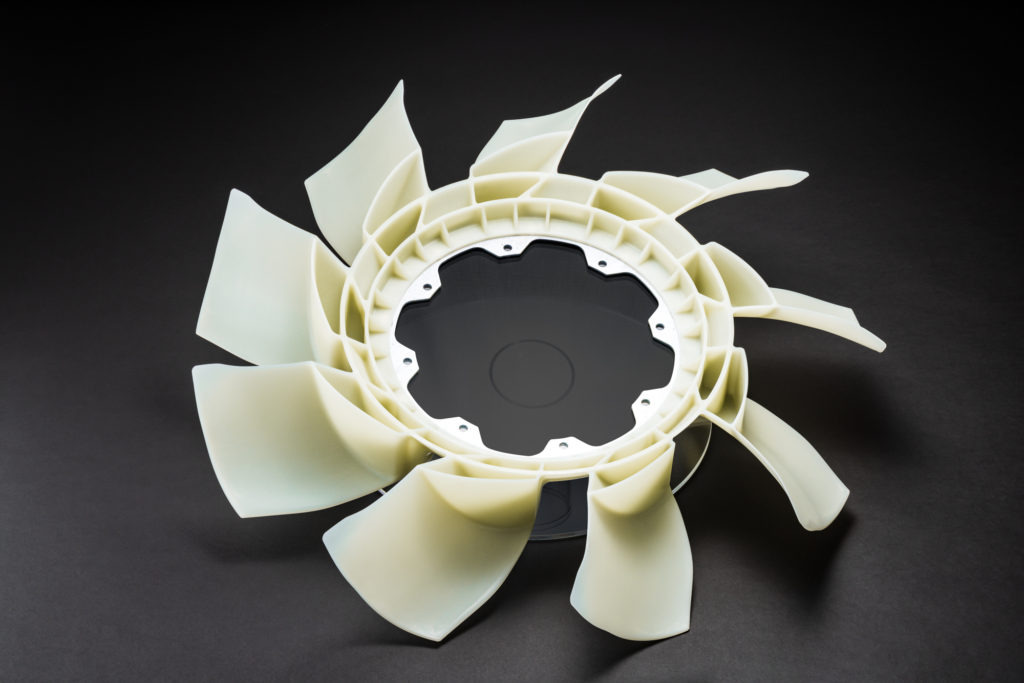

Plastic Cooling Fan

In 1963 USUI successfully developed the world's first plastic made fan for automobile engine cooling and has been manufacturing the Plastic Cooling Fan since then.

BreFin TUBE™

BreFin TUBE™ is our product broadly used for hydraulic oil piping with coolability, such as power steering oil piping and engine oil piping.

|

Engine Related Products

Push rod

USUI Push Rod is a hollow bar type product, which consists of a short tube with an upper end (cup shaped) and a lower end (ball shape). On a tube end, an upper end is joined and on another end, a lower end is joined with projection weld.

EGR Tube

EGR(Exhaust Gas Recirculation) Tube returns a part of exhaust gas in the engine.

OIL & WATER TUBE for Turbo Charger

OIL & WATER TUBE for Turbo charger is a pipe offering a flexible connection with high heat and high corrosion resistance as a supercharger in supporting low fuel consumption technology as well as high output of engine. High Pressure Fuel Tubes for Gasoline Direct Injection Engine

Technology of Gasoline Direct Injection system is expanding in order to improve efficiency of gasoline engine. Meanwhile, wide variety of fuels such as ethanol blended fuel is also gradually being distributed.

AHI Tube

AHI (After treatment Hydrocarbon Injection) TubeAHI(After treatment Hydrocarbon Injection) tube is for diesel combustion burner systems.

UL-FLEX® TUBE

UL-FLEX™ is a flexible tube that has excellent flexibility and can flexibly absorb relative displacement between installations. Our unique ByPitch construction method provides a high degree of freedom in piping design, allowing us to respond to prototype production and construction changes in a short period of time.

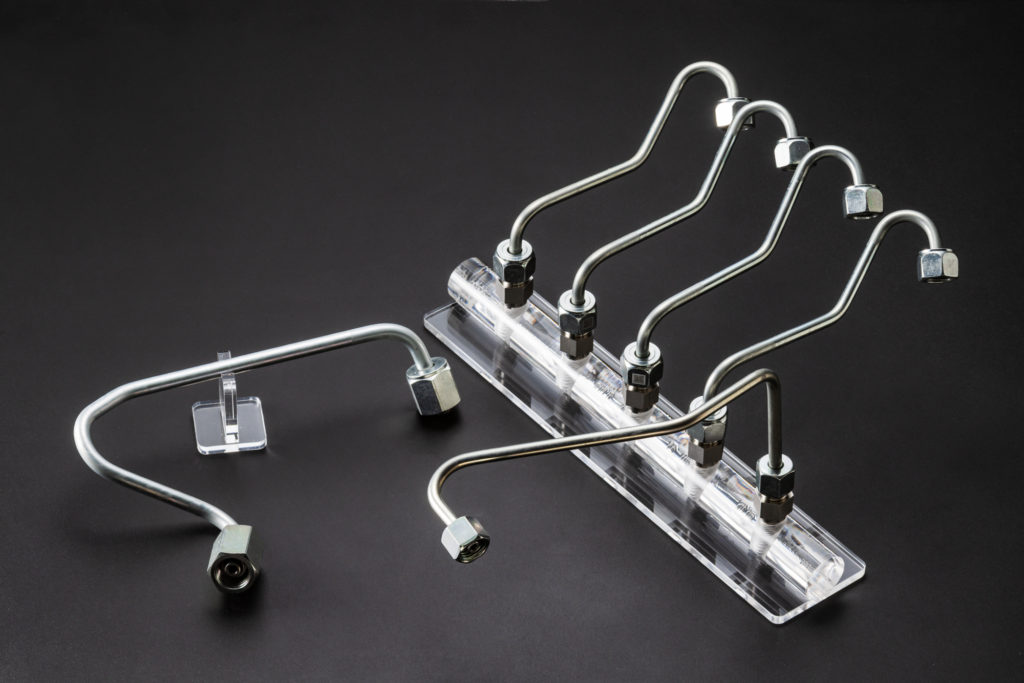

Fuel Rail (UFRID™)

As an approach for reducing fuel evaporative emission, adopting fuel returnless system on gasoline engine vehicles are considerably increased. The system adopted will cause larger fuel pressure pulsation and therefore pulsation dampening should be required on the fuel rail.

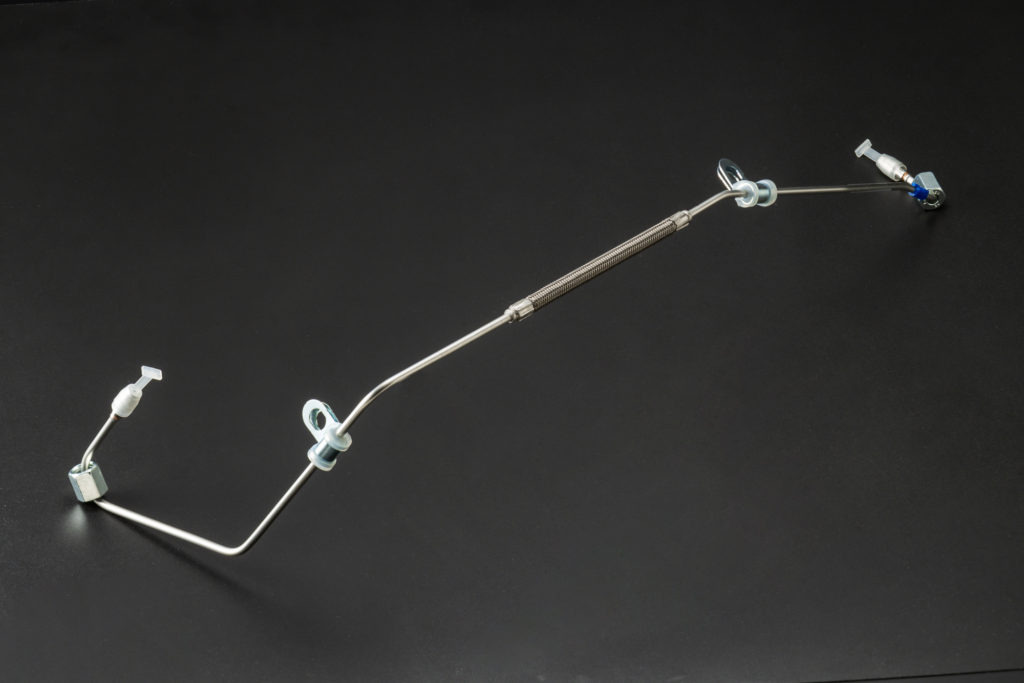

Fuel Injection Tube(USIT™-SP)

USIT™-SP is the world's first tube which was adopted for common rail diesel fuel injection systems among several high-pressure injection tubes. The Common rail fuel injection system plays a very important role in diesel emission control today.

|

Functional Products

Liquid Separator

Liquid SeparatorFeature

● Achieve high collecting performance under high gas flow rate

Applications

● Component for separaing and collecting condensed water from intake and exhaust route of engine.(Especially Low Pressure Loop-EGR route).

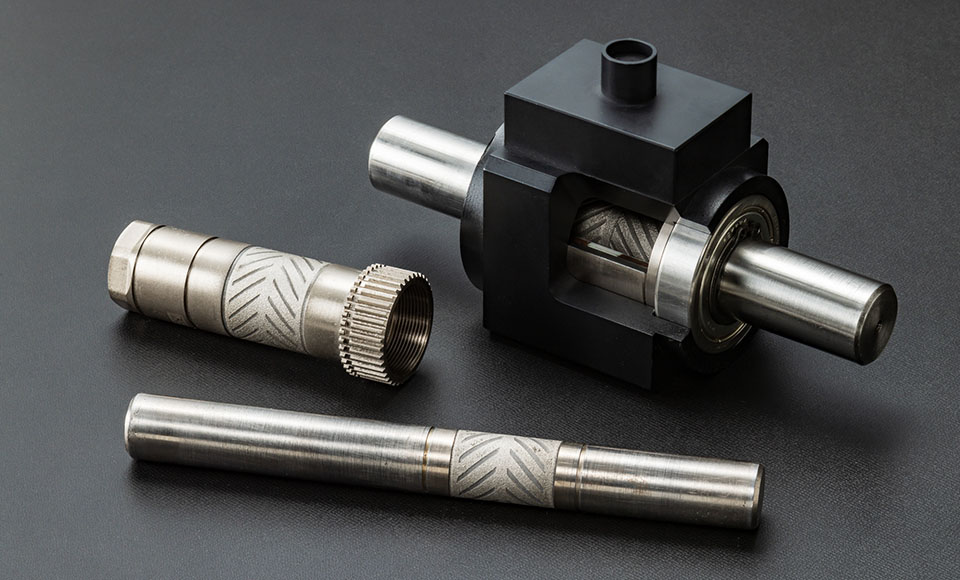

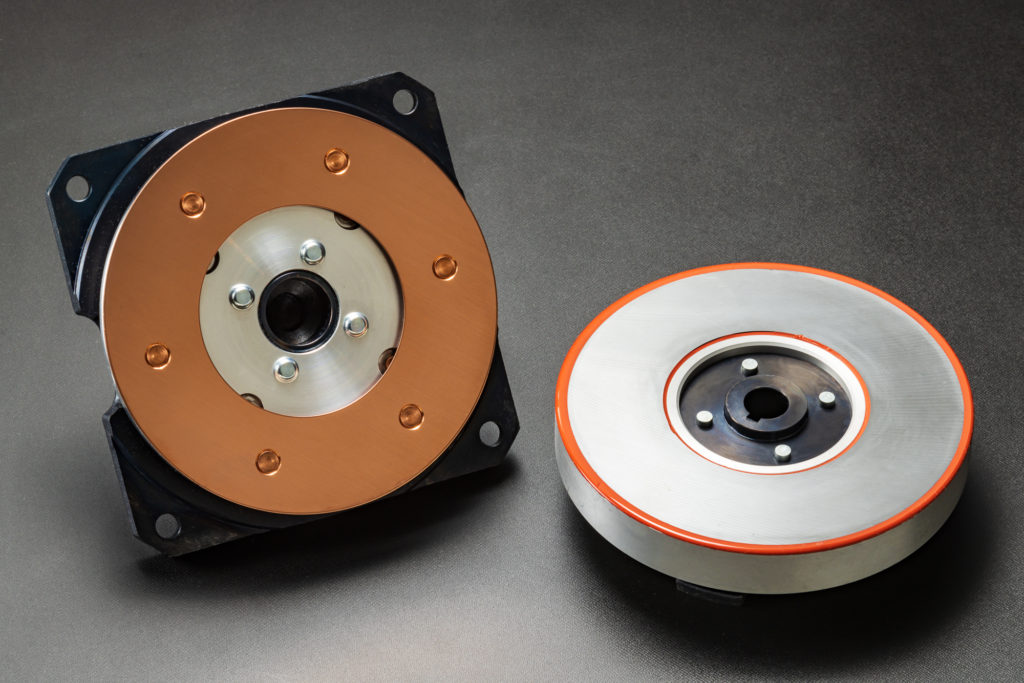

Magnetic Coupling

Magnetic Coupling is a clutch applying hysteresis in magnet. In clutch, permanent magnets and hysteresis material are put together facing each other closely but not contacting. These clutches have a constant torque feature. And also the limit on transmitting torque is very stable through the service life, virtually un-limited life since permanent magnets are used.

U-TIGHTSEAL®

U-TIGHTSEAL™U-TIGHTSEAL® is a metal gasket with a built-in elastic core (coil spring). Although it is made of metal, it exhibits properties similar to elastomer (rubber) due to its excellent compression and recovery properties.

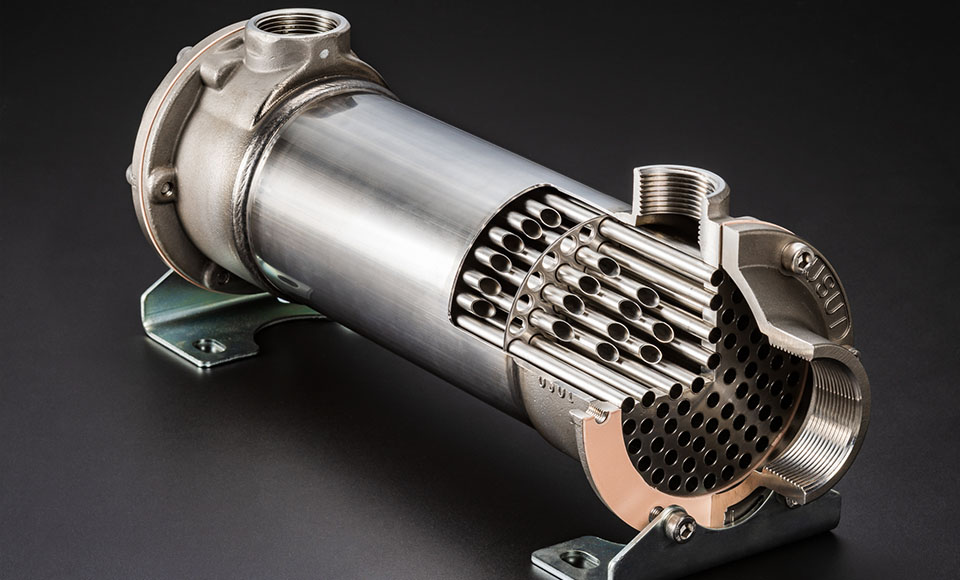

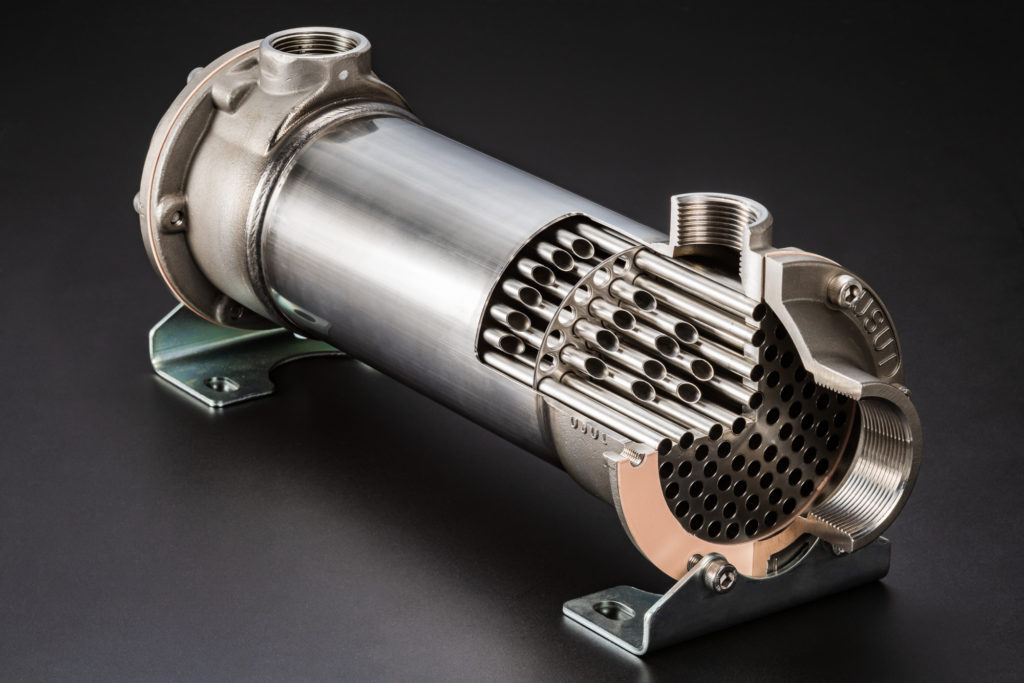

Heat Exchanger

Heat ExchangerUSUI tubular exchangers have the reputation for a wide variety of models, moderate prices, and short delivery, since USUI had started research and development on the equipment. And currently, the exchangers are adopting various uses and purposes such as water heating systems and bathing facilities; preheating and heat recovering. FeatureThanks to the best tube layout and proprietary baffles, which are equipped with press formed collars, the exchangers have higher heat exchanging performance and superior vibration durability.

|